Suivez-vous

- YouTube

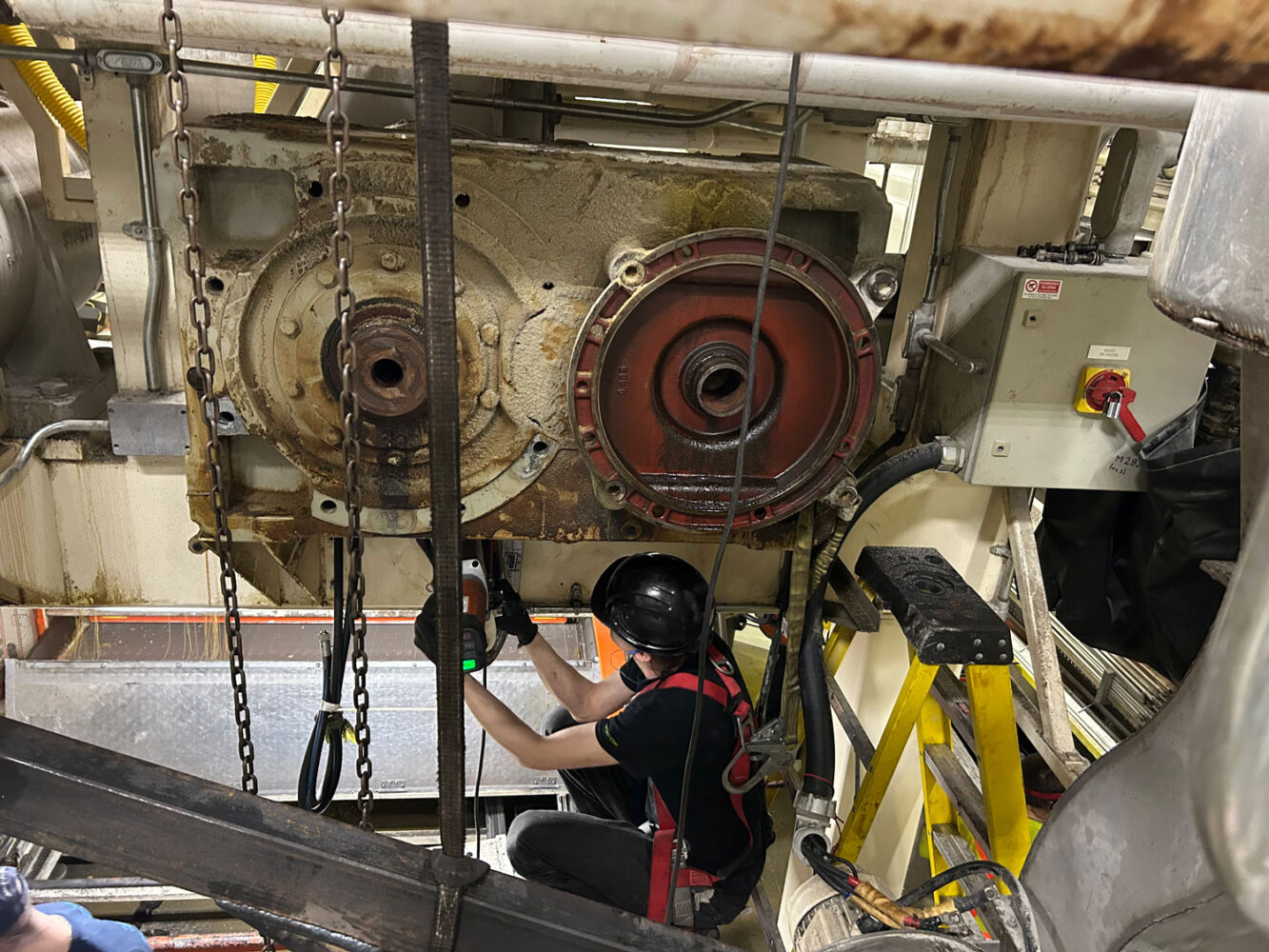

The gear motor, which is essential to the proper functioning of the pasta production extrusion line, was defective. This part plays a critical role in ensuring the correct power output and motor speed reduction, two parameters that are essential to guaranteeing the quality of the final product and the production rate.

To meet this challenge, LM quickly mobilized two specialized technicians who completely replaced the gear motor in just five working days. This rapid and efficient intervention allowed operations to resume quickly.

But LM’s efficiency does not stop with the speed of execution. The choice of the new gear motor and the quality of its installation also brought real technical gains.

The installed gear motor ensures efficient operation by adapting the motor speed to production requirements, while increasing the torque available for demanding applications such as extrusion. Its reliability and durability make it an ideal choice for intensive industrial environments. Thanks to its versatility, it can be easily integrated into different equipment, facilitating future maintenance. Finally, its quick installation by LM contributes to a significant reduction in downtime, ensuring optimal continuity of operations.

LM’s rapid and controlled intervention enabled the customer to avoid a prolonged shutdown of its production line, thus protecting its operational efficiency and delivery times. Thanks to the replacement of the gear motor, production was able to resume without compromising product quality, ensuring continuity of supply to its customers.

In economic terms, this responsiveness limited the financial losses associated with downtime, while enhancing the overall reliability of the equipment. The new unit, which is robust and perfectly suited to the extrusion line’s needs, offers long-term performance guarantees, reducing the risk of future breakdowns.

Finally, this successful operation has strengthened the relationship of trust between the customer and LM, demonstrating the latter’s ability to respond effectively to critical technical issues with professionalism and rigour.

By working with LM, this customer was able to protect its production line and maintain its quality commitments.