Suivez-vous

- YouTube

Many of the hospital’s fans are located in restricted areas that are inaccessible during normal operating hours. This made it difficult for technicians to access the equipment to take vibration measurements, which are essential for detecting early signs of mechanical problems. The isolation of the equipment and the inability to intervene during the day made it challenging to maintain regular and reliable vibration data monitoring. It was therefore crucial to ensure monitoring without disrupting the hospital’s daily operations.

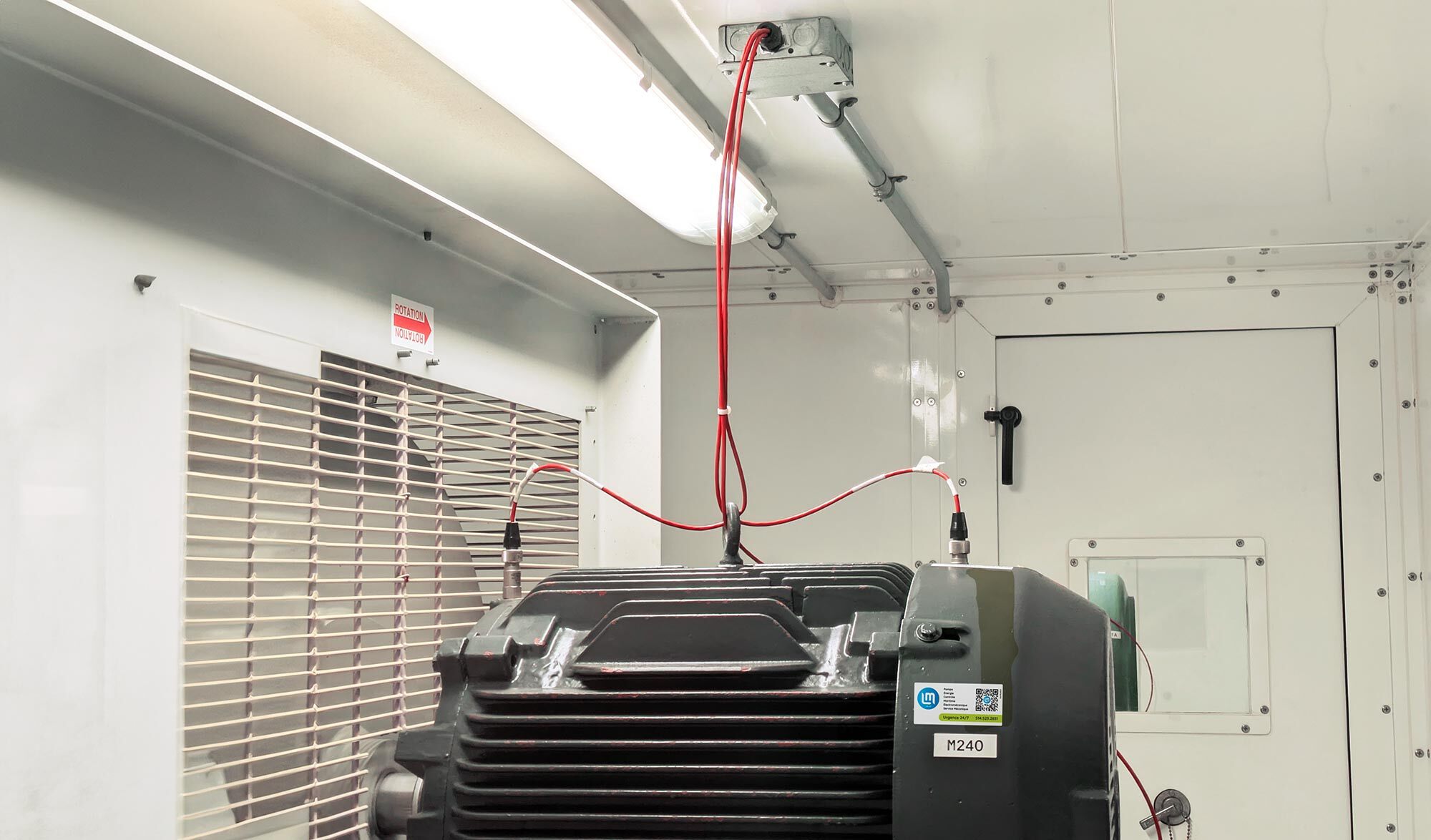

LM proposed installing permanent vibration sensors directly on the motor structures. These sensors collect vibration data from outside confined areas. A connection cable is routed to an external junction box, allowing technicians to take vibration readings during daylight hours, thereby optimizing preventive maintenance. This solution enables regular monitoring of critical equipment without interrupting hospital activities or physically accessing hard-to-reach areas. The LM team visits the site monthly to collect data and carry out maintenance work requested by the customer, such as motor replacement, fan balancing, and other tasks.

Thanks to the integration of these sensors, the hospital now benefits from high-quality monitoring without the need for invasive interventions. The data collected enables accurate assessment of equipment health, classifying anomalies according to their severity (normal, minor, moderate, severe, and critical). This allows the hospital to plan maintenance proactively, reducing the risk of unexpected failures and ensuring optimal equipment performance. The decision to reduce waste collection to regular weekday hours, rather than evenings or weekends with overtime, has resulted in a significant reduction in hospital operating costs.